Solar panel manufacturing is a complex process that involves sourcing materials, such as steel and aluminum, and creating individual components from them. This process is essential for producing solar panels that power homes and have industrial applications.

In recent years, suppliers and creators have increasingly focused on bringing solar panel manufacturing back to the US. In this blog post, we will discuss the steps and stages of the solar panel manufacturing process, as well as global sourcing and how it impacts the industry.

Did you know many of Kloeckner Metals’ nationwide branches boast special processing capabilities for the solar industry? Download our solar brochure now to see how Kloeckner Metals can service your solar needs.

Solar panel manufacturing begins with collecting raw materials. Typically, these include metals like aluminum and steel, as well as silicon, silver, and tempered glass. The metal is then formed into cells, which are the basic building blocks of the solar panel. Each cell is made up of layers of doped semiconductor material that is patterned to maximize the energy produced.

The cells are then cut into individual wafers and placed in a grid pattern on a substrate. This substrate is often made of a metal alloy such as aluminum or copper. An interconnected ribbon is placed across the substrate to connect each cell to the next. Then, all of the components are encapsulated in an anti-corrosion, waterproof, and fireproof material for protection.

Next, electrical connections are added so that the cells can be linked together and connected to a power source. A special electrical coating is then applied to the back of the panel to increase its efficiency. Finally, it’s all assembled into a frame, covered with tempered glass, and connected to wiring that leads to a battery or other power source.

After assembly, the panels undergo rigorous testing to ensure they meet industry standards and customer requirements. After testing, they are ready to be installed and put to use.

As a solar panel frame, metal helps ensure a long-lasting, durable, and strong structure. Aluminum is a great material to use due to its corrosion resistance, light weight, and ability to withstand extreme temperatures. Steel is often used in solar panels as well, typically in junction boxes and connecting components. It is an ideal material for these parts as it can tolerate a higher temperature range than aluminum while also providing superior strength and durability.

In addition to steel and aluminum, other metals are used to manufacture solar panels. Copper is used as the electrical contact and bus bar material, as it has good electrical conductivity. Silicon is also used to make up the photovoltaic cells which convert sunlight into electricity. These components, combined with aluminum frames and steel connecting components, form the basis of solar panel manufacturing.

When it comes to manufacturing solar panels, sourcing the materials used is a major factor in the overall cost and efficiency of the product. Solar panel components can be sourced from various parts of the world, depending on the product’s quality and availability.

Solar panel manufacturers often rely on countries like China, India, and Malaysia for sourcing materials. Recent global supply chain fractures and weak links have created supply concerns. In 2021, China controlled 84% of the world’s solar panel manufacturing capacity while accounting for just 36.4% of solar panel demand. The U.S. and Europe, by contrast, make up more than ⅓ of demand for solar panels but less than 6% of its capacity. When supply chains between China and the U.S. snarl, break, or weaken, U.S. manufacturers and suppliers face severe shortages.

Consequently, the United States is actively positioning itself to be a major player in global solar panel manufacturing. This is due to a number of factors, such as falling costs and advancements in technology. The US also has access to an abundance of renewable energy sources, making it an attractive destination for solar panel manufacturers. These efforts are supported by both federal and local governments, as well as private industry.

The federal government offers tax incentives for companies that manufacture solar panels in the US, making it more attractive for companies to invest in domestic manufacturing facilities. Additionally, decreased costs driven have made it more cost-effective for companies to consider domestic production.

Local and state governments are doing more to partner with solar panel producers. Property and production taxes along with improved environmental quality offer direct benefits. Communities such as Madison, Wisconsin have used solar panel projects as opportunities to train and develop unemployed residents in solar-related jobs. These partnerships may help to make solar panels more affordable for consumers and encourage more widespread adoption of the technology.

The benefits of bringing solar panel manufacturing back to the US are significant. Not only does it provide employment opportunities for American workers, but it also boosts the economy, increases energy independence, and reduces environmental impacts associated with shipping materials overseas. It also helps to further advance the solar industry as a whole, providing greater access to technology and helping to develop new and innovative products.

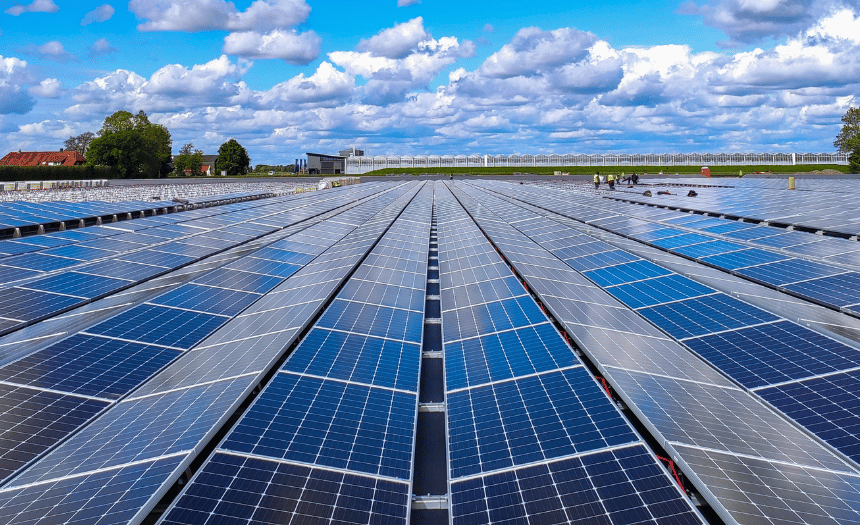

Solar energy is an increasingly popular option for powering industrial applications. Solar panels are being used for canopies, warehouses, and other industrial buildings due to their cost-effectiveness and low maintenance needs. In addition, the fact that solar panels are able to produce clean, renewable energy makes them a desirable alternative for many businesses looking to reduce their carbon footprint.

Solar panels for industrial applications are larger and more powerful than those used in residential homes. For example, commercial solar panels can range in size from 250 to 400 watts per panel. These larger, more powerful panels can help businesses generate significantly more electricity than would be possible with residential solar panels.

In addition, the lifespan of solar panels used in industrial applications is generally much longer than residential solar panels. Industrial solar panel systems are designed to last up to 30 years or more, depending on the type of system and components used. This can help businesses save money over the long term by avoiding costly repairs and replacements.

Solar energy is also an attractive option for industrial applications because it is easy to scale up as needed. If a business decides that they need more electricity, they can simply add more solar panels to their system. This allows businesses to expand their energy production without having to invest in additional infrastructure or equipment.

Overall, solar panels are a great option for powering industrial applications. They offer long-term cost savings, flexibility in scalability, and the ability to produce clean, renewable energy. With the right system, businesses can harness the power of the sun and enjoy the benefits of solar energy for years to come.

Did you know many of Kloeckner Metals’ nationwide branches boast special processing capabilities for the solar industry? Download our solar brochure now to see how Kloeckner Metals can service your solar needs.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: