Steel is one of the world’s oldest and most vital commodity materials, the second-largest in the world to be exact. That makes it a global economy staple for many industries – automotive, household appliances, construction, aviation, and the list goes on. It’s no secret that the conversation about steel production has evolved over the last few years. To put it plainly, if you plan to continue working in the steel business, you have to adopt new sustainability standards that are important to eco-sensitive clients. We’re pleased to join our holding company in carbon-neutral initiatives that will achieve that.

The Greenhouse Gas Protocol defines accounting standards for emissions scopes, and the best way to understand them is by thinking of them as co-existing efforts contributing to the same timeline. Meaning: Scope 1 isn’t the first phase but instead, it runs concurrently with Scope 2 and Scope 3.

Raw material extraction and production of the steel we purchase account for around 96.5% of our emissions, whereas our operations account for about 3.2%. That covers anything involving our facilities, equipment, and upstream and downstream transportation. This means we’ll be making the switch to options that burn fewer or no fossil fuels.

One shining example of our first steps in embracing Scope 1 is Kloeckner Santa Fe Springs upgrading from a diesel railcar mover to an electric version. Electric provides the power to ensure the day-to-day work gets done, but it also means we’re not burning diesel fossil fuels. We do understand that electric motors alone will not help us clear the hurdle, which means we’ve been purchasing Renewable Energy Credits (RECs) to serve our needs in Scope 2. This enables us to support the renewable energy market. We’re also looking into implementing other types of electric vehicles and trying to figure out how we move away from using tools like acetylene burning torches.

We’re ready to invest in the future, and the biggest obstacle is that the infrastructure needs to fall in line with the development of electric equipment. We are excited to share more soon about an electric fleet truck prototype we’ll be testing in Santa Fe Springs this month, but that’s for another blog. In other words, we would buy an electric fleet for every branch tomorrow, if they do the work we need them to, but there wouldn’t be places to charge all the trucks right away. Some regions are equipped and some are just beginning to take strides in that direction. We’re having these conversations now so we’ll be ready when charging access and other accommodations are readily available.

Juggling the facets of Scope 1 goes hand-in-hand with expanding our knowledge and making accommodations for Scope 2. We don’t have control over electric utility companies and must work off of the energy mix they provide. What we can do is feed the carbon-neutral cycle by going solar, wherever possible, and using leftover energy to charge any electric vehicles or equipment we acquire.

As we dip our toes into the kind of alternative power it’ll take to support more electric vehicles, another charge (pun intended) we’re taking on is buying renewable energy credits from vetted sources that contribute to the grid. Our support in that production doesn’t just take care of us; it creates a more viable market for all. Basically, we will buy these credits and have solar or wind energy generated on our behalf when we can’t install a solar panel of our own. We’ve come a long way from borrowing a cup of sugar!

The changes don’t begin and end with production. The shift to reduce carbon emissions will affect the entire supply chain. The trend has already been moving toward big manufacturers demanding more and more Green Steel. We see this challenge as an opportunity, especially concerning the natural recyclability of steel. Our strong partnerships with American mills have given us an advantage in recycling scrap since most of them already use the less carbon-intensive Electric Arc Furnace production method. We’ll continue to leverage those relationships to create completely circular supply chains where the scrap generated is sold back to the producing mill to be melted again.

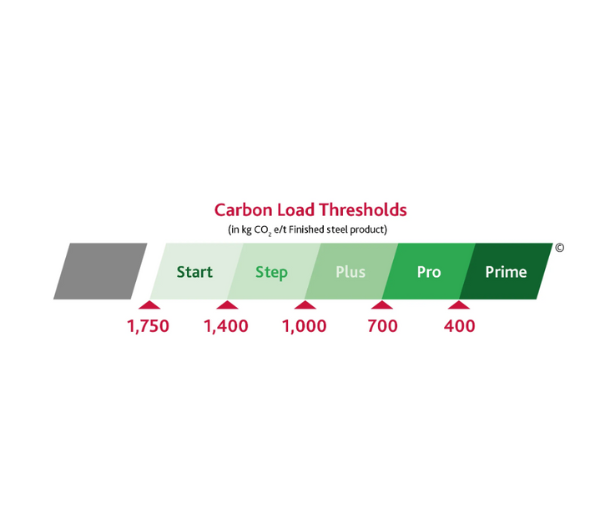

Another critical piece of the great race to Green Steel involves simplifying certificates and labels in a way that empowers customers to compare authenticity and quality. We knew things could get pretty sticky very quickly if we hesitated to assign these values, so we’ve created and already offer the universal CO2 reduced steel metric displayed below. No guesswork, no wasted time!

Our categorization of Green Steel also holds us accountable to our targets, which we’ve clearly outlined well into 2030. The items we considered for our basis include customer demand, steel producer perspectives, steel production technology routes, and the GHG Protocol as the leading carbon accounting standard. We’re confident this will not only add transparency to the developing market, but it ensures efficiency in every touch point we make with a customer, existing or new, as we move further into Green Steel territory.

This scope also goes beyond battery, paper, scrap, and plastic recycling in our spaces; this scope touches on topics of transportation and business travel, which are things we’ve been tightening up on for a while. Our hybrid work-from-home policy not only affords employees a greater work/life balance, but it also means we’re commuting a lot less, cutting down on individual emissions for the greater good.

Investing in the future and becoming more sustainable isn’t a scary topic, but there are a lot of moving parts to begin understanding what needs to be done. We hope this has been an approachable, informative article for anyone who is considering going green. The time to take action is now, and we’re ready to be your partner for a more sustainable tomorrow!

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: