Continuous casting machines are some of the most popular machines in the production line when it comes to aluminum. Continuous casting allows metals like aluminum to be stretched, shaped, and solidified all without any need for any pauses or interruptions. The benefits are obvious: higher yield and cost savings. For some products, like battery grids, it is now the standard.

But, there are two major types of continuous casting methods: direct chill and continuous chill (sometimes also called semi-continuous). Both methods use the same principle of solidifying an aluminum alloy in an open mold under controlled conditions, but the end results are quite different!

Kloeckner Metals is a full-line aluminum supplier and service center. Download our aluminum spec sheet and check what Kloeckner Metals routinely stocks.

Read on to learn about what distinguishes direct chill from continuous cast aluminum and what your main consideration should be before choosing one versus the other.

There are two main types of aluminum casting — continuous cast (CC) and semi-continuous cast (SCC). These terms refer to how quickly the molten aluminum solidifies after it leaves a tundish (reservoir at the top of the mold).

Although both direct chill and continuous cast aluminum are types of cast aluminum, there are some differences.

First, let’s start with direct chill. Direct chill casting usually describes the fabrication of rectangular or cylindrical ingots. They’re further processed by rolling, forging, or other methods to create sheets, plates, or other products.

With extrusion-cast aluminum, direct chill involves forcing molten metal through a nozzle to form long, thin tubes that can be further shaped into sheets or other products by rolling or flattening them. The resulting product is known as foil-cast aluminum because it’s often so thin that it resembles foil in appearance.

If you were to hold up a piece of foil-cast aluminum against your skin, it would feel like wearing silk underwear—that’s how light it is! And if you bent or creased it even slightly (it won’t tear), it would spring back into place almost immediately because its composition allows for flexibility.

Direct chill casting is a process that lets manufacturers cast aluminum directly from liquid metal into a mold. Since it doesn’t have to be formed in a rolling mill, direct chill is more cost-effective than traditional methods, but it is still more expensive than continuous casting. It also creates fewer energy costs and releases less carbon dioxide into the atmosphere.

As an alternative to billet aluminum, direct chill is often used for oil or gas line fittings and decorative items like wheels for tractors or wagons. However, its use isn’t limited to commercial applications. Direct chill can also be used for household products like garden shears and hoses.

Continuous cast aluminum is a manufacturing process that results in aluminum ingots of uniform size, shape, and weight. More importantly, it can produce alloys in large quantities, but is preferred when quality is less important a characteristic in the final product. Unfortunately, despite being the more cost effective option of the two methods, it is more limited in end use applications.

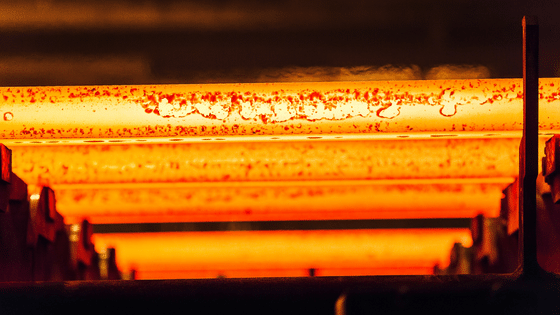

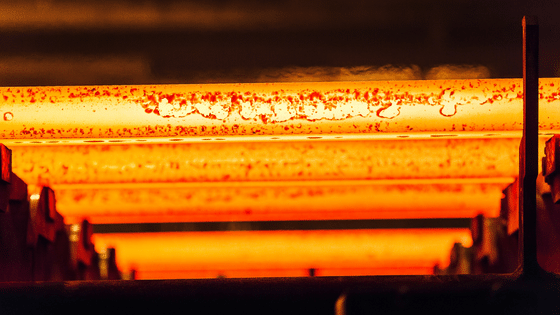

In continuous casting, molten metal is poured into a water-cooled mold set at an angle to allow gravity to draw out the solidifying ingot. It is then cut into bars or extruded through a die to form ribbons. This kind of casting uses just one furnace and produces an alloy that does not need much further processing for use in everyday products like automobile parts, household appliances, or electronics components.

The main advantage of direct chill is quality. The direct chill process allows for more control over every step of manufacturing, ensuring that your resulting aluminum part will be of superior quality and surface appearance. In addition, if you choose a company that has certifications in place, such as UL or ISO 9001, you’ll be able to count on them to produce high-quality parts each and every time.

The main advantage of continuous cast aluminum is cost savings.

One of the main disadvantages of direct chill aluminum over continuous cast aluminum is that, since direct chill requires a fast freeze, it’s more likely to form air pockets or trapped water. These can make for weaker and less durable parts.

Another disadvantage of direct chill casting is that it has a smaller capacity than continuous cast aluminum and costs more than other types of casting processes. Additionally, products may have inconsistent dimensional tolerances because there are fewer quality checks with direct chill compared to continuous cast process.

The main disadvantage of continuous cast aluminum is the reduced quality and the limit in end use applications. If quality and surface appearance are less important components of your project, it may be beneficial to consider the continuous cast process for the cost savings as long as it is suited for your end use.

The direct chill method of casting uses three basic pieces of equipment: a ladle, a furnace, and a caster. It differs from continuous casting in that its use of pouring metal into chilled containers for solidification instead of molding it as one continuous piece.

One challenge to direct chill casting is that every individual cast has to be cooled before it can be removed from its mold. This creates longer turnaround times than continuous casting, which allows for more pieces to be cast at once by cooling them simultaneously with water or oil jets.

Continuous casting works similarly to how poured aluminum products such as beverage cans are made. Molten aluminum is continuously poured into an open-ended rotating mold while carbon dioxide gas is injected into it. When all of the aluminum has been added, liquid slag begins to form around its surface, and a skin begins to form over the top of it (called bruising).

Then, an electric current is applied through rollers attached to each end of a conveyor belt so that they can push against each other and generate enough force for a perfect solidified product!

There are many differences between direct chill and continuous cast aluminum in regard to applications. The most notable difference comes down to strength and functionality. Continuous cast aluminum parts tend to be much more functional than their direct chill counterparts, mainly because they are heat-treated after solidification. A good example of a continuous cast application would be rain gutters, where price is a higher priority than quality or surface appearance. In general, however, end use applications are more limited for the continuous cast process.

Depending on how close a part needs to fit, either type may be suitable for an application, but depending on how complex or intricate a part must be for function or aesthetics, continuous cast aluminum parts may be better suited to your needs. If a part does not require great strength or any complex geometry or fabrication, then direct chill aluminum would likely work well for you.

Kloeckner Metals is a full-line aluminum supplier and service center. Kloeckner Metals combines a national footprint with the latest fabrication and processing technologies and most innovative customer service solutions. Contact us at Kloeckner Metals to help determine which kind of aluminum might be right for your project.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: