Summertime is grilling time. As the smell of grilled deliciousness wafts through the air, take a moment and appreciate your grill. Yes, your grill. Chances are, enameling steel made all this amazing goodness possible.

Enameling steel does much more than build a grill, though. “It goes into washers, dryers, hot water heaters, even bathtubs… many different products,” says Mike Branigan, Carbon Flat Rolled Product Manager of Kloeckner Metals. “It’s probably more common than we think.”

Enameled steel, sometimes called porcelain-enameled metal or porcelain-on-steel, refers to steel that has been coated with a layer of enamel. Enamel is a type of glass fused onto the surface of the steel through a high-temperature firing process.

The steel core supplies strength and support, while the porcelain coating protects the metal from environmental elements and wear and tear. This coating provides both aesthetic appeal and enhanced functionality, making the steel more resistant to corrosion, stains, and scratches. By combining these two materials, enameled steel provides unique properties that make it stand out from other metals.

Enameled steel is a versatile and durable material that is used in many applications where high performance and aesthetics are critical, including home appliances, cookware, building panels, and even automotive parts. Its unique properties make it a popular choice for products that require resistance to high temperatures, chemicals, and corrosion.

Enamel is a glass-like material that is applied as a coating to a metal surface. It is composed of various minerals, including silica, feldspar, borax, and pigments. Some enamels may contain additional materials like pigments, which are used to give the enamel its color. Other additives like fluxes and binders may also be used to improve the adhesion and durability of the enamel.

These components are carefully formulated to achieve desired properties such as hardness, color, and resistance to heat and chemicals. The composition of enamel can vary depending on the specific application and manufacturer.

To make enamel, the glass is melted together with the minerals at high temperatures, forming a liquid that can be applied to the metal. When the enamel is cooled and solidified, it creates a smooth, durable surface that is resistant to chipping, scratching, and corrosion.

Porcelain-enameled steel is typically made by applying a layer of enamel coating to steel that has been prepped to be able to accept the enamel coating. The type of steel that is typically used for this process is low-carbon steel or mild steel. However, stainless steel and other high-performance alloys can also be enameled.

Not all steel grades are suitable for enameling due to their chemical composition and surface characteristics. Low-carbon steels with a smooth surface and good formability are commonly used for enameling. ASTM A424 is one popular grade for enameling, but the specific metal grade selected depends on the desired application and performance requirements.

The use of porcelain on steel dates back to the early 19th century when manufacturers were searching for a way to protect metal surfaces from rust and corrosion. Initially, the metal product was heated, dusted with enamel, and immediately fired in a kiln.

Most of this early enameled metal was used to manufacture kitchen utensils, decorative items, and even military helmets. Later on, manufacturers discovered that it could be used to create large appliances, such as stoves, refrigerators, and washing machines. Porcelain on steel not only protected the metal surface from corrosion but also gave it an aesthetically pleasing look.

As demand grew, manufacturers began to develop more advanced methods of producing porcelain-enameled steel. They experimented with different metal grades, enamel formulations, and manufacturing techniques to create stronger, more durable products. Today, porcelain-enameled steel is a widely used material for a variety of applications, ranging from kitchen sinks to industrial tanks. Its history may be long, but its usefulness remains undiminished

The creation of porcelain-enameled steel involves a meticulous process. The steel is first cleaned and pre-treated to ensure proper adhesion of the enamel. A layer of enamel, typically in powder or liquid form, is then applied to the steel surface. The enameled steel is subjected to high temperatures in a kiln or furnace, where the enamel fuses with the steel, forming a durable, glass-like coating.

The enamel is typically a combination of powdered glass and various minerals that are melted onto the steel surface at extremely high temperatures. This process is called vitrification, and it bonds the enamel to the steel to create a durable, corrosion-resistant surface.

The exact composition of the enamel mixture can vary depending on the intended use of the final product. For example, enamel used for cooking appliances may contain materials that make it more heat-resistant, while enamel used for outdoor furniture may contain materials that make it more weather-resistant.

After the enamel has been applied, the steel is heated again to allow the enamel to harden and fully bond with the steel. Once cooled, the porcelain-enameled steel sheet can be cut, shaped, and finished according to the desired product specifications.

Enameling steel is formable, which allows it to be formed into many different applications. It is specially designed so that enamels will better adhere to the metal. The surface roughness is designed to encourage adhesion. Also, compared to regular steel, it has less carbon and the products’ chemistry allows for hot enamel to adhere.

The low carbon and surface roughness is imperative for preventing defects while applying the enamel coating. Not only does the adhesion of the enamel matter, but the appearance is also important as well. If the carbon content of the metal is too high, then it can cause the release of gaseous CO and CO2 during the firing process. This can impact the appearance of the surface.

Enameled steel offers numerous benefits and advantages that make it a popular choice in various industries. These include:

Enameled steel offers a multitude of benefits. It combines the strength and durability of steel with the smooth, non-porous, and easy-to-clean surface of enamel. Enameled steel is resistant to chemicals, heat, and impact, making it a reliable choice for demanding environments. It also provides excellent color retention, ensuring long-lasting beauty.

Enameled steel has numerous applications across various industries. Due to its durability and versatility, it is a preferred choice in the production of kitchen appliances, construction materials, and transportation equipment.

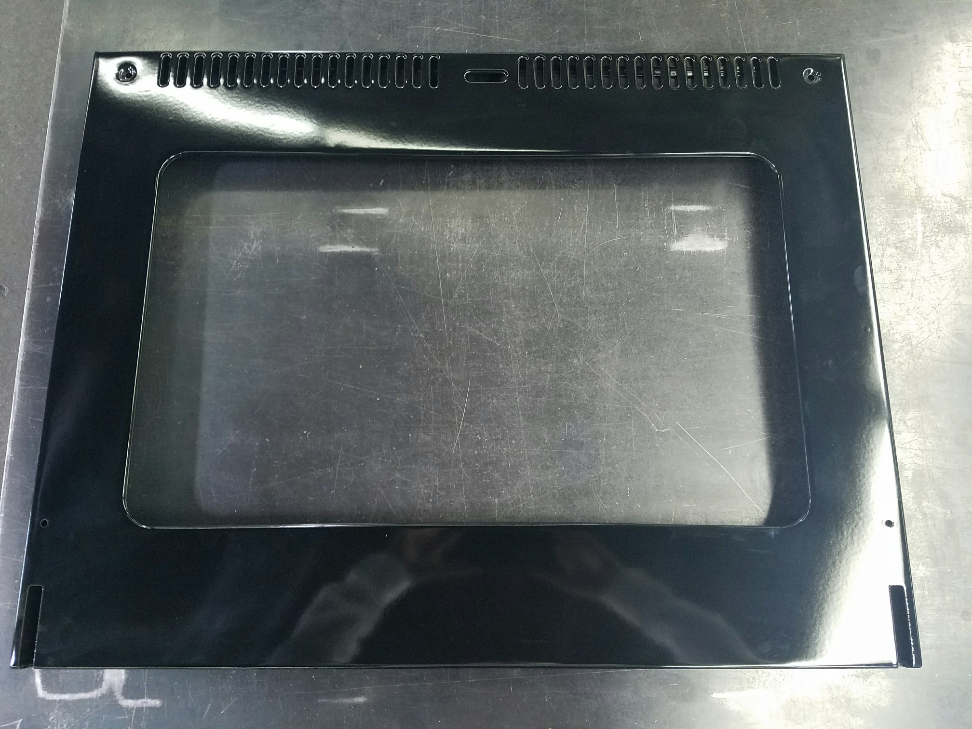

Its ability to withstand high temperatures, resist corrosion, and retain heat makes enameled steel a perfect material for ovens, refrigerators, and stoves. Due to the metal’s weather resistance and aesthetic appeal, construction materials producers use it to make roofing and cladding materials as well as fixtures and fittings for buildings.

Enameled steel is also a popular choice in the transportation industry, where it is used to manufacture vehicles such as buses, trucks, and trains. Its corrosion resistance and durability make it ideal for withstanding harsh weather conditions and exposure to different environments.

Apart from the above applications, porcelain-enameled steel is also used in the production of outdoor furniture, barbecues, and decorative items such as sculptures. Its aesthetic appeal and durability make it a preferred material in these applications.

While enameled steel is known for its durability and resistance to rust, it is still important to maintain and care for it properly to ensure its longevity and appearance.

First, clean enameled steel regularly, preferably after each use. Use a soft cloth or sponge and mild detergent to remove any dirt or grease buildup. Avoid using harsh chemicals or abrasive cleaning materials as this can damage the enamel coating.

If any stains or burnt-on food residue is present, soak the affected area with warm soapy water for a few minutes before gently scrubbing it away. Be sure to rinse the surface thoroughly with clean water afterward to prevent any soap residue from affecting the enamel.

It is important to avoid using metal utensils or abrasive tools on enameled steel as this can scratch the enamel and cause damage to the coating. Instead, use plastic or wooden utensils when cooking on this type of surface.

When storing enameled steel cookware, be sure to avoid stacking pieces on top of each other as this can cause scratches and damage to the enamel.

Lastly, inspect enameled steel regularly for any signs of damage such as cracks or chips in the enamel coating. If any damage is present, it is recommended to stop using the cookware until it can be repaired or replaced.

With proper maintenance and care, enameled steel can provide years of reliable use and maintain its beautiful appearance.

Porcelain-enameled steel combines the strength and durability of steel with the beauty and functionality of enamel. Its unique properties make it a sought-after material in a diverse range of applications, from household appliances to architectural elements. The meticulous enameling metal process, along with the selection of suitable metal grades and the composition of enamel, ensure the creation of reliable and visually appealing enameled steel products.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: