Metal Fabrication shops provide a multitude of services, including punching, cutting, forming, and welding. They can perform soft tooled processes and some hard tooled stamping. From the mill, the metal travels to a service center where it is processed into the desired blank sizes, or the desired coil widths. It is then shipped to the fabrication shop, where it is made into the component parts and sometimes even assembled.

“It adds a degree of comfort, and makes it easier for the customer, because we can provide one stop shopping if you will,” says Terry Woodward of American Fabricators (AFI), a Kloeckner Metals fabrication shop. “Before this came about, a company may have had a separate invoice for raw material, another invoice for fabrication labor, an invoice for post plating, galvanizing, etc. and then maybe an invoice for shipping.”

Kloeckner can provide all these services on a single invoice, streamlining the process for the customer. In the past, a fabricator may have only provided parts at the component level. As time went on, though, customers needed help with additional services. These services included assembly, kitting, line sequences, and all the metal finishes. The fabrication center has evolved to meet these demands.

“In some cases we’ve even produced a finished assembly where all that the customer does is put their label on it, if you will,” Woodward says. “A lot of finished parts require multiple processes. A customer wants ease of doing business, so if we can provide everything under one roof, it makes it a lot easier for them.

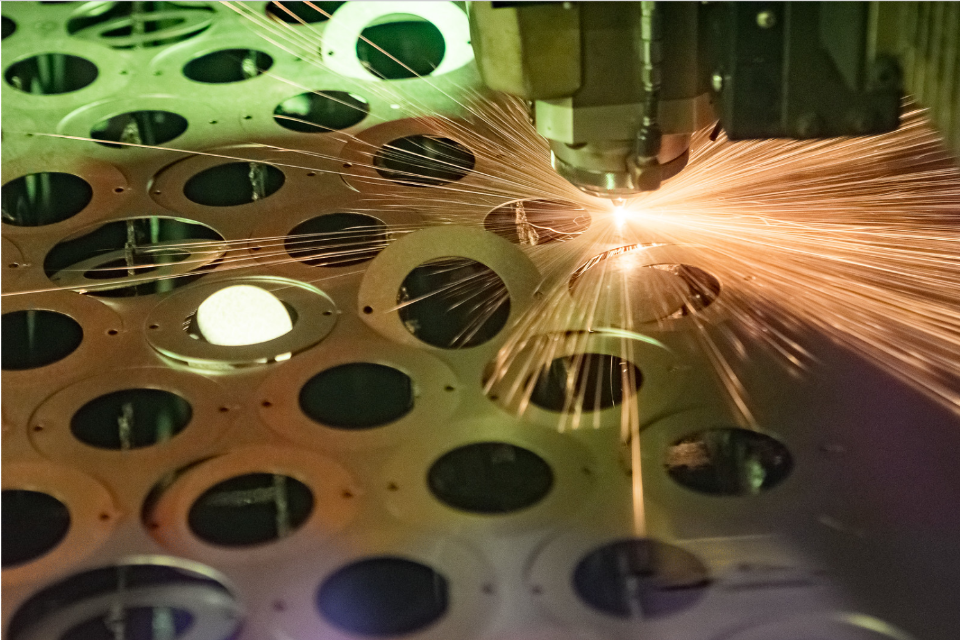

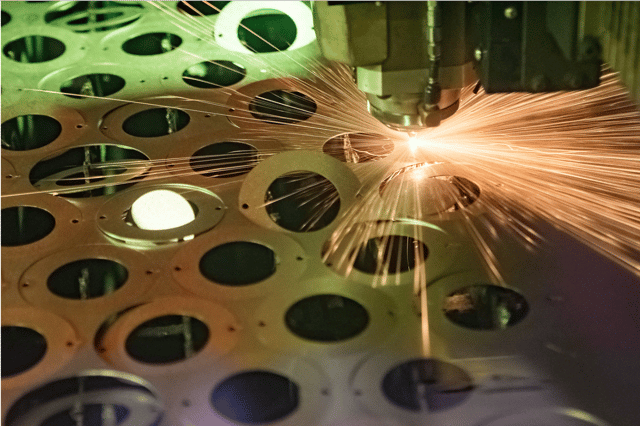

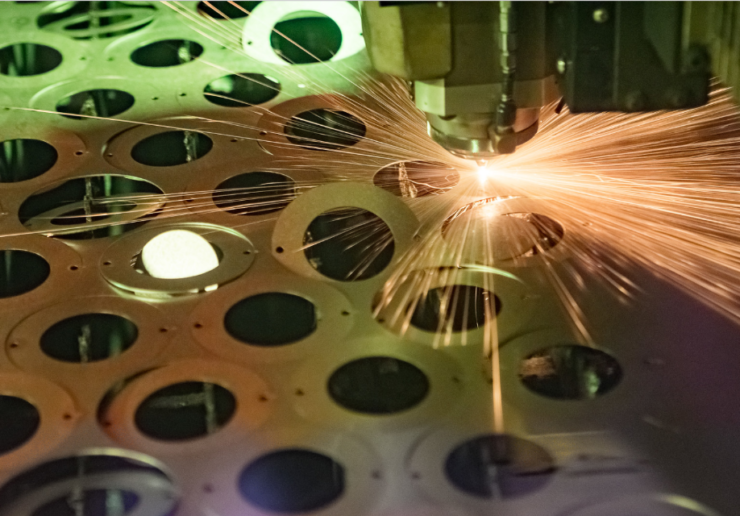

The many processes required to make a finished product necessitate that the fabrication shop house a variety of machines to perform the necessary tasks. These machines must be able to handle a variety of metals, including prepainted, galvanized, and stainless steel. At AFI, for example, they work with many different materials, such as aluminum, stainless, hot rolled, cold rolled, and all different gauges.

“When you walk into a Kloeckner Nashville facility and you see 6 lasers, 16 turrets, and 30+ press breaks, multiple welding stations, and a lot of capability, it is pretty impressive,” Woodward says.

Additionally, Kloeckner has duplicative equipment at most facilities. This helps minimize the risk of a slowdown in production resulting from a breakdown or maintenance issue. Duplicative machines are particularly important in high volume orders where a bottleneck can cause a significant backup.

“If we simply have one or two machines, and we got busy, then we had a breakdown, then you lose 50% of your capability,” Woodward says. “Through the years the leadership and ownership at AFI saw the wisdom in having duplicate equipment.”

Keeping up with technology and having the correct machinery is important. With the cost of maintenance and down time, there is a point where a machine becomes obsolete. Therefore, it is important to invest in new machinery, while maintaining a balance that matches current and future demands.

Utilizing a fabrication shop can save a great deal of money. In addition to the convenience of having all these services available in one place, the cost of transit is reduced. Further reducing this cost is Kloeckner’s ability to ship multiple parts and products together.

“You don’t have transit and freight bouncing a product around from place to place,” Woodward says. “One of the advantages to using Kloeckner in that process is that in a lot of cases freight is an issue, but it can be shared by different products and thereby lower the cost for the customer.”

By providing a streamlined process that goes all the way from the mill to the customer, Kloeckner eliminates costs that come with multiple vendors. Kloeckner’s multitude of in house machines allows for most processes to be performed under one roof, further reducing shipping cost.

“Everybody wants three things: they want quality, they want on time delivery, and they want a reasonable cost structure,” Woodward says. “At one time people would say pick any two of the three, but in today’s world you really need to be a leader in all three areas.”

When working with parts that will compose a finished product, it is important to ensure quality. This is particularly true when a part is going to appear on the exterior of the product. In these cases, extra care must be given to make sure that the part is free from aesthetic defects.

“We always train and caution our operators to be on the lookout, both on incoming raw material what we are seeing before it feeds into our process, and then at every multiple station or point within our process,” Woodward says. The result is almost a 100% inspection from point to point.

Working with prepainted and galvanized materials also requires care. Many of the prepainted parts are going to be visible to the end customer, and the finishes can make them more delicate.

“It’s in the handling of those materials, as far as the loading and unloading into the machines, because they do have a tendency to scratch,” Woodward says.

The bottom line is to provide services that allow a customer to create a better product. It is important to provide fabrication services with care and precision, whatever the demands of a specific part may be.

“All of this is geared toward allowing a customer to make more and sell more of their finished product,” Woodward says. “That’s what it all boils down to.”

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: