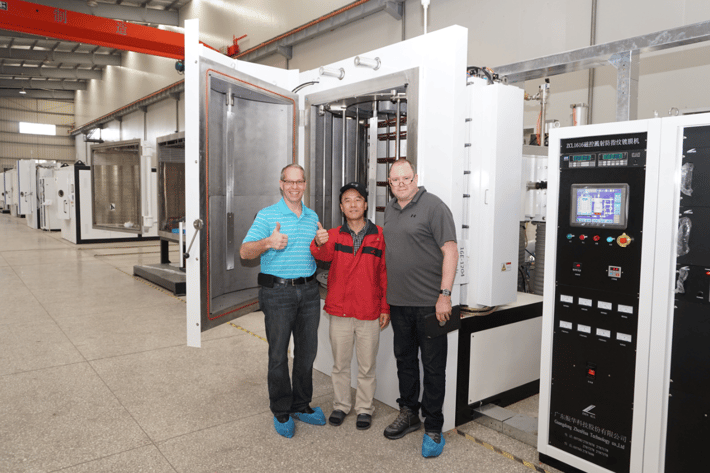

Kloeckner Metals Corp. will install new physical vapor deposition (PVD) processing equipment at its Cincinnati facility this year in order to expand its value-add portfolio and capitalize on growing demand for more capacity and color options in surface-treated stainless steel.Kloeckner Metals haspartnered with China’s Double Stone Steel Ltd. (DSS) in 2014 to produce and market PVD products via Kloeckner in North and South America.

Kloeckner Metals Corp. will install new physical vapor deposition (PVD) processing equipment at its Cincinnati facility this year in order to expand its value-add portfolio and capitalize on growing demand for more capacity and color options in surface-treated stainless steel.Kloeckner Metals haspartnered with China’s Double Stone Steel Ltd. (DSS) in 2014 to produce and market PVD products via Kloeckner in North and South America.

Following a planning phase with DSS, the new equipment will be installed this year and is expected to be fully operational by the end of 2017.

PVD is a color surface-treatment that is produced when a metallic vapor is deposited via a vacuum chamber onto a target surface or object, enhancing surface properties and aesthetics. Kloeckner’s new equipment will enable the coloring of stainless steel and certain aluminum materials domestically.

Our Vice President, Commericial – Stainless and AluminumJohn Dobek is spearheading the program. Dobek says, “Until now, PVD in the United States has never been brought to a scale that goes beyond just components as it has only available in limited size ranges. Large-scale projects andsourcing for colored sheets and larger-scale profiles traditionally have had to rely on imported material, resulting in complex supply chains, longer lead times and more freight costs.”

Dobek noted that PVD is already offered fairly broadly in nations such as Russia and China. But now, on a global basis, it has beengaining significant traction in the appliance, food equipment, conveyance, transportation and electronic segments, in addition to its prominence in architectural design applications.

Dobek predicts that this market is growing worldwide at a year-over-year rate of 8 to 9 percent and the projections are that this will continue to grow year over year because of the applicability across end markets.

As a result, Kloeckner is optimistic that it will see significant growth from its offerings in North America. Those offerings will include stainless sheets up to 60 inches wide and 144 inches long, parts and profiles up to 144 inches long, and fabrication in similar configurations subject to weight limitations. Kloeckner will also have anti fingerprint options available applied via an in chamber process that improves durability and longevity of this attribute.

Dobek concludes that we’re the pioneers in terms of the market niche that we aspire to be in. Even though the technology is here, Kloeckner will fill a gap with it’s the capacities and scale.

![]()

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: