Kloeckner Metals is proud to carry a Vernon beam splitter to increase the efficiency and accuracy of our metal processing operations.

Answer:

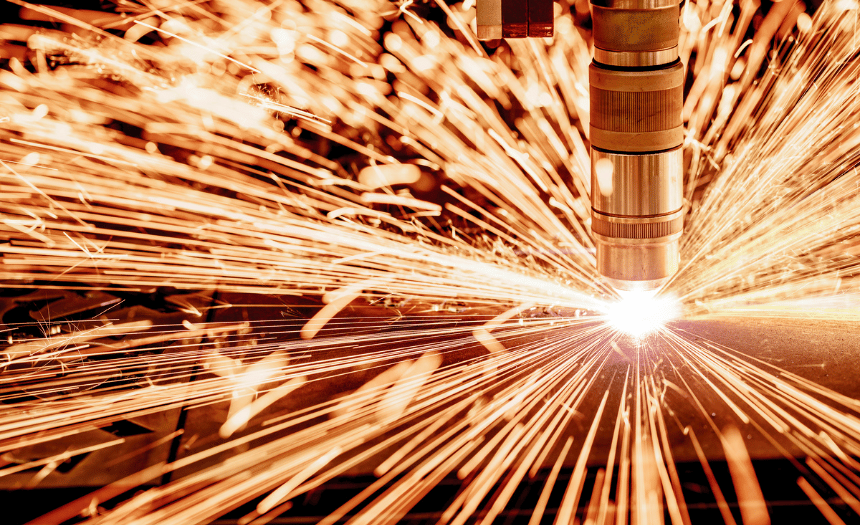

In the metals industry, a beam splitter typically refers to a type of optical sensor used in various types of metal processing equipment, such as laser cutting or welding machines. It is used to split the laser beam into multiple beams, which can then be directed to different parts of the processing equipment.

The beam splitter in metal processing equipment can be used for a variety of purposes, such as allowing the laser beam to be directed at multiple parts of a workpiece simultaneously or to monitor the laser power and intensity during the processing. By using one, manufacturers can increase the efficiency and accuracy of their metal processing operations.

Beam splitters used in metal processing equipment are typically made from high-quality optical materials, such as quartz or fused silica, to ensure that they are able to withstand the high-intensity laser beams and provide accurate readings. The specific design and properties will depend on the requirements of the processing equipment and the desired output specifications.

Answer:

ASTM carbon metal grades that are frequently processed with a beam splitter in metal processing equipment include:

The specific ASTM carbon metal grades processed will depend on the requirements of the processing equipment and the desired output specifications for the final product. Beam splitters are often used in laser cutting of carbon steel, which can produce high-quality, precise cuts with minimal distortion or discoloration.

What is a beam splitter?

Answer:

In the metals industry, a beam splitter typically refers to a type of optical sensor used in various types of metal processing equipment, such as laser cutting or welding machines. It is used to split the laser beam into multiple beams, which can then be directed to different parts of the processing equipment.

The beam splitter in metal processing equipment can be used for a variety of purposes, such as allowing the laser beam to be directed at multiple parts of a workpiece simultaneously or to monitor the laser power and intensity during the processing. By using one, manufacturers can increase the efficiency and accuracy of their metal processing operations.

Beam splitters used in metal processing equipment are typically made from high-quality optical materials, such as quartz or fused silica, to ensure that they are able to withstand the high-intensity laser beams and provide accurate readings. The specific design and properties will depend on the requirements of the processing equipment and the desired output specifications.

What ASTM carbon steel grades are frequently processed with a beam splitter?

Answer:

ASTM carbon metal grades that are frequently processed with a beam splitter in metal processing equipment include:

The specific ASTM carbon metal grades processed will depend on the requirements of the processing equipment and the desired output specifications for the final product. Beam splitters are often used in laser cutting of carbon steel, which can produce high-quality, precise cuts with minimal distortion or discoloration.

It’s time to celebrate one of our veteran branches, located just outside of...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: