SA516 is the most popular pressure vessel steel plate in the industry and Kloeckner Metals is proud to supply it routinely across our nationwide network of branches.

SA516 steel plate is the most popular pressure vessel quality steel plate. It is available in four different grades, 55, 60, 65 and 70. It is also offered in normalized condition where high notch toughness is required.

SA516 is a high value pressure vessel quality steel plate that provides an optimum combination of strength, notch toughness, and weldability. It is designed to withstand moderate to low temperatures and resist corrosion. One disadvantage is that it is not easily formed or machined.

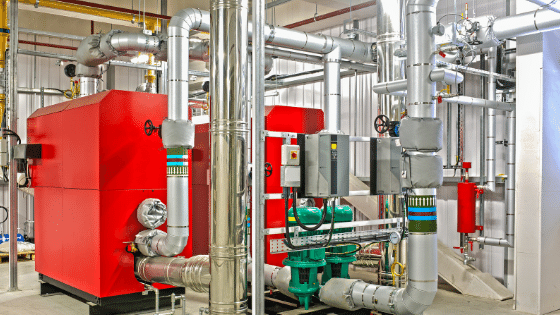

The grade meets high performance standards required by oil, gas, and petrochemical industries for use in boilers and pressure vessels. It is also common in the construction, automotive, and railroad industries.

SA516 is primarily used in welded stress vessels and industrial boilers, where it controls a moderate to low temperature with improved impact toughness. SA516 grade 70 is especially popular in power stations, reactors, heat exchangers, separators, various kinds of tanks, pressure shells, and boiler drums. Other components, like gas cylinders, high-pressure water pipes, and turbine volutes are also common. Some additional applications include automotive parts, structural tubing, and bridges.

SA516 has fair machinability.

It has excellent weldability.

SA516 is heat treatable.

SA516 is a high value pressure vessel quality steel plate that provides an optimum combination of strength, notch toughness, and weldability. It is designed to withstand moderate to low temperatures and resist corrosion. One disadvantage is that it is not easily formed or machined.

The grade meets high performance standards required by oil, gas, and petrochemical industries for use in boilers and pressure vessels. It is also common in the construction, automotive, and railroad industries.

SA516 is primarily used in welded stress vessels and industrial boilers, where it controls a moderate to low temperature with improved impact toughness. SA516 grade 70 is especially popular in power stations, reactors, heat exchangers, separators, various kinds of tanks, pressure shells, and boiler drums. Other components, like gas cylinders, high-pressure water pipes, and turbine volutes are also common. Some additional applications include automotive parts, structural tubing, and bridges.

SA516 has fair machinability.

It has excellent weldability.

SA516 is heat treatable.

Out of the four grades—55, 60, 65, 70—that are available for this steel, grade 70 is considered the most widespread. While each grade is a pressure vessel quality high carbon low alloy steel plate, tensile strength varies among them. Grade 70 has the highest tensile strength of them all, between 485 – 625 MPa.

SA516 steel is the American Society for Testing and Materials (ASTM) designation for Pressure Vessel Quality (PVQ) carbon steel plate available in normalized condition. It shows a tensile strength between 380 – 620 MPa, depending on the grade. Higher chemical composition and material properties standards are set for PVQ steel because it is specifically meant to contain gasses or liquids at elevated pressures.

Grade 60 and 70 are nearly identical, and for most applications, they will both prove suitable. However, when more strength is required, grade 70 will outperform. It is the highest strength grade. The three other grades, including grade 60, all have lower tensile strengths. The tensile strength for grade 60 is between 415 – 550 MPa, while grade 70 has a tensile strength between 485 – 620 MPa.

Out of the four grades—55, 60, 65, 70—that are available for this steel, grade 70 is considered the most widespread. While each grade is a pressure vessel quality high carbon low alloy steel plate, tensile strength varies among them. Grade 70 has the highest tensile strength of them all, between 485 – 625 MPa.

SA516 steel is the American Society for Testing and Materials (ASTM) designation for Pressure Vessel Quality (PVQ) carbon steel plate available in normalized condition. It shows a tensile strength between 380 – 620 MPa, depending on the grade. Higher chemical composition and material properties standards are set for PVQ steel because it is specifically meant to contain gasses or liquids at elevated pressures.

Grade 60 and 70 are nearly identical, and for most applications, they will both prove suitable. However, when more strength is required, grade 70 will outperform. It is the highest strength grade. The three other grades, including grade 60, all have lower tensile strengths. The tensile strength for grade 60 is between 415 – 550 MPa, while grade 70 has a tensile strength between 485 – 620 MPa.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: