A285 is a carbon steel intended for fusion-welded applications and Kloeckner Metals is proud to supply it routinely across our nationwide network of branches.

It is a carbon steel that is formable and strong. It is intended for fusion-welding in applications like pressure vessel boilers, tanks, and heat exchangers. It has three grades: A, B, and C.

It is easy to form, machine and weld. This grade is specifically intended for fusion-welded pressure vessels and is not recommended for structural and other applications.

It is seen in the oil and gas industry.

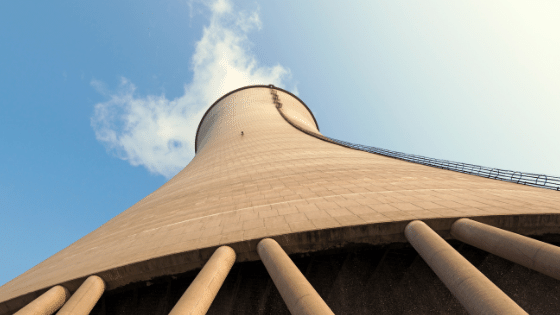

It is intended for all kinds of fusion-welded process vessels, heat exchangers, and storage tanks. This includes: columns, reactors, gravity separators, boiler drums, and cooling towers.

It has good machinability.

It has excellent weldability.

It is heat treatable.

It is easy to form, machine and weld. This grade is specifically intended for fusion-welded pressure vessels and is not recommended for structural and other applications.

It is seen in the oil and gas industry.

It is intended for all kinds of fusion-welded process vessels, heat exchangers, and storage tanks. This includes: columns, reactors, gravity separators, boiler drums, and cooling towers.

It has good machinability.

It has excellent weldability.

It is heat treatable.

There are three grades of this steel: A, B, and C. All grades are meant for fusion-welded pressure vessels. They increase in tensile strength from A to C, and their chemical properties vary slightly. For more information regarding the specifications for all three grades, please see the ATSM standards.

A283 is a low carbon structural steel. Only SA283 steel plate would be viable for similar pressure vessel applications to A285.

Grade C shows the highest tensile strength at 380 – 515 MPa.

There are three grades of this steel: A, B, and C. All grades are meant for fusion-welded pressure vessels. They increase in tensile strength from A to C, and their chemical properties vary slightly. For more information regarding the specifications for all three grades, please see the ATSM standards.

A283 is a low carbon structural steel. Only SA283 steel plate would be viable for similar pressure vessel applications to A285.

Grade C shows the highest tensile strength at 380 – 515 MPa.

Steel base plates are fundamental elements employed in various manufacturing processes. These flat, rectangular...

Metal fabrication is a critical process that transforms raw metal materials into finished products....

The solar industry has undergone a significant transformation by incorporating steel products into various...

The unprecedented pace of solar growth is challenging and reforming America’s construction and engineering...

If you’ve got a roof over your head, it’s partly thanks to purlins. A...

Acquiring highly profitable company with annual sales of around USD 30 million Significant expansion...

A stainless steel depot is a specialized facility or supplier that stocks and provides...

American manufacturers use about 28.2 billion pounds of aluminum every year, 41.6% of it...

Leading steel distributor expands commitment to sustainability in the North American market. Kloeckner Metals,...

At Kloeckner, we are excited to announce that our Santa Fe Springs, CA location...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: