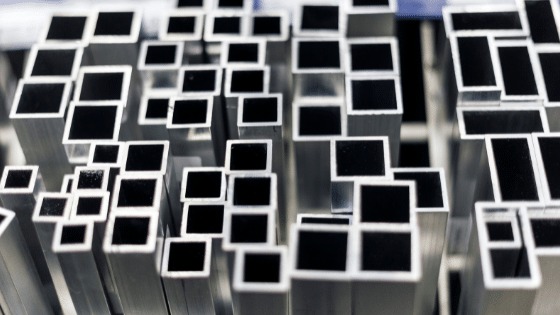

Kloeckner Metals is proud to supply round, square, and rectangular steel tube nationwide across our network of branches.

ASTM A-513 Type 1 is a low carbon steel. It shows tighter dimensional tolerances on outer diameter, wall thickness, and length than A500, and is more easily bended. It is one of the highest value steel tubing available.

It’s routinely stocked in the following formats:

A500 is available in two grades, B and C. GR B is a cold formed welded and seamless carbon steel available in round, square, and rectangular structural tubing for welded, riveted, or bolted construction. It shows excellent weldability and good machinability. Common applications include: bridges and buildings, and for general structural purposes.

A500 GR C is available in square and rectangular structural tubing. Similar to grade B in many ways, it distinguishes itself with higher yield and tensile strengths.

ASTM A-513 Type 1 is a low carbon steel. It shows tighter dimensional tolerances on outer diameter, wall thickness, and length than A500, and is more easily bended. It is one of the highest value steel tubing available.

It’s routinely stocked in the following formats:

A500 is available in two grades, B and C. GR B is a cold formed welded and seamless carbon steel available in round, square, and rectangular structural tubing for welded, riveted, or bolted construction. It shows excellent weldability and good machinability. Common applications include: bridges and buildings, and for general structural purposes.

A500 GR C is available in square and rectangular structural tubing. Similar to grade B in many ways, it distinguishes itself with higher yield and tensile strengths.

This widely popular hollow steel product is most often used for mechanical or structural purposes across industries. It is available in round, square, and rectangular shapes in varying thicknesses and lengths.

ANSWER:

The main difference between these two products is their chemical composition. Carbon steel has higher carbon content than stainless steel and a lower alloy content. As a result, carbon steel is more susceptible to rust when exposed to moisture. In addition to a significantly lower carbon content, stainless steel has a much higher chromium content. The added chromium protects against corrosion and oxidation. Read our blog post on when to use stainless steel vs carbon steel to learn more.

ANSWER:

They are measured in their outer dimensions, gauge/wall thicknesses, and length. Typical sizes include 11 gauge, 1/4”, 3/8” and 5/8” at the 20′, 24′, 40′ and 48′ lengths.

ANSWER:

It is a hollow steel product in the shape of a rectangle.

ANSWER:

High demand in growing industries like construction, architecture, and automotive make this a popular steel product. It is designed for structural applications and manufacturing industries because its shape offers greater strength and rigidity than other tubes.

ANSWER:

Typical square sizes include: 1/2″, 3/4″, 5/8″, 7/8″ and 1″ in 11, 14, 16, 18, and 20 gauges. They can be easily cut to custom lengths.

ANSWER:

Because of its excellent strength and durability, this product is seen widely across industries — from construction and architecture to aerospace manufacturing. It is also easy to cut, bend, and form.

ANSWER:

The main difference between these two products is their chemical composition. Carbon steel has higher carbon content than stainless steel and a lower alloy content. As a result, carbon steel is more susceptible to rust when exposed to moisture. In addition to a significantly lower carbon content, stainless steel has a much higher chromium content. The added chromium protects against corrosion and oxidation. Read our blog post on when to use stainless steel vs carbon steel to learn more.

ANSWER:

They are measured in their outer dimensions, gauge/wall thicknesses, and length. Typical sizes include 11 gauge, 1/4”, 3/8” and 5/8” at the 20′, 24′, 40′ and 48′ lengths.

ANSWER:

It is a hollow steel product in the shape of a rectangle.

ANSWER:

High demand in growing industries like construction, architecture, and automotive make this a popular steel product. It is designed for structural applications and manufacturing industries because its shape offers greater strength and rigidity than other tubes.

ANSWER:

Typical square sizes include: 1/2″, 3/4″, 5/8″, 7/8″ and 1″ in 11, 14, 16, 18, and 20 gauges. They can be easily cut to custom lengths.

ANSWER:

Because of its excellent strength and durability, this product is seen widely across industries — from construction and architecture to aerospace manufacturing. It is also easy to cut, bend, and form.

Between our global footprint, international transportation network,...

When Hurricane Katrina struck New Orleans in 2005, it destroyed homes and upended entire...

Steel is one of the most widely used materials available. It’s crucial for modern...

If you only knew him by his job title—Manager of Data Privacy and Information...

The Kloeckner Metals Building Products Group will be at booth #6065 at MetalCon in...

This article by Brad Kuvin originally appeared in MetalForming Magazine. Following its acquisition of...

Divestment marks another important milestone in the execution of the strategy “Klöckner & Co: Leveraging Strengths – Step...

When safety is on the line, whether it’s an armored vehicle, body armor, or...

In South Carolina’s culinary circles, the name Jamie Sanderson is well known. He’s the...

Less than 200 years ago, workers erected the first utility pole, which was designed...

Anthony Kilgore doesn’t rush to be the loudest in the room, but if you...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: