This article originally appeared in the June, 2020 issue of The Boss Magazine.

At no other moment in the past half-century has transparency and responsiveness been so essential to the health and longevity of global industry. Digitization is helping astute organizations maintain the agility required to continually improve despite dramatically uncertain market conditions.

We recently spoke with John Ganem, CEO of Kloeckner Metals Corporation, one of North America’s biggest players in the metals manufacturing, supply, and service sector, about digital preparedness and keeping critical supply chains inviolable in times of crisis.

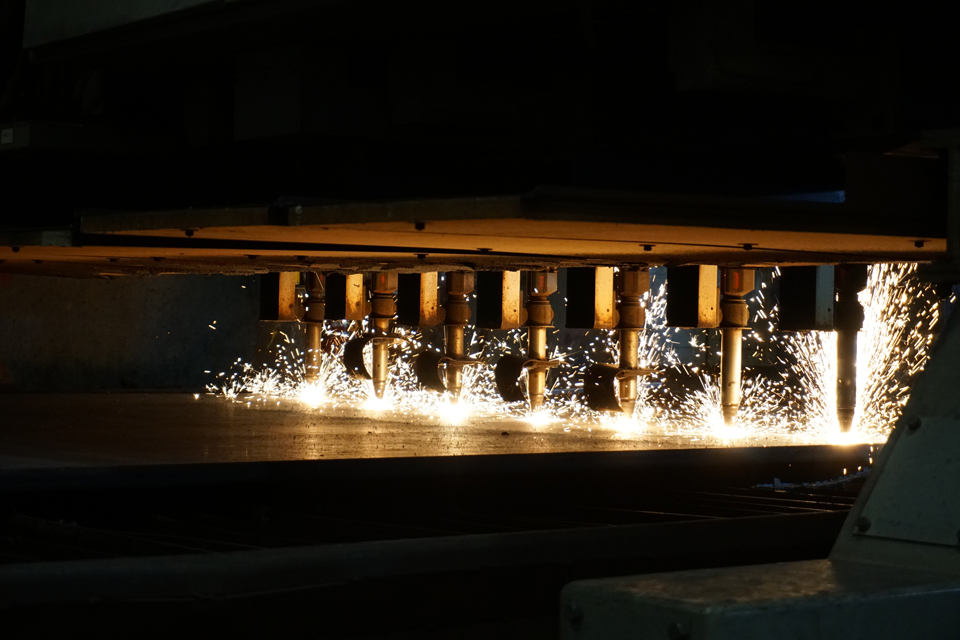

A member of the Duisburg, Germany-based Klöckner & Co Group, one of the world’s largest distributors of metal products, Kloeckner Metals features a broad and deep product line with over 200,000 SKUs. A full line manufacturing, production, and service center, Kloeckner Metals processes and ships carbon and non-ferrous metals from 47 facilities in the US and Mexico. They make and distribute carbon flat roll, plate steel, stainless, aluminum, bar, structural, and other kinds of metal for virtually every industry.

“We have a national footprint and a very diverse offering,” Ganem said. “Most of the time we’re adding some value to the product that is produced, and then shifting that to the customers who are consuming the product. We go anywhere from aluminum to flat-rolled products that are used in industries such as automotive, appliance, electrical, heavy plates for ships and vessels as well as structural products used in construction.”

The company dove into the digital age early on. Their transformation from a legacy industrial manufacturer to a leading-edge player leveraging automation to increase productivity, efficiency, and customer confidence has been careful, measured, and fearless. “We are on the forefront of using digital technology, and as a result we are well prepared for what’s coming at us with the coronavirus,” he stressed.

“We’re able to quickly react to the new reality of everybody working from home without any issues. That’s probably not the case for most of our competitors because we’ve been working toward this transformation for the last few years, but that’s just one part of the new reality we’re facing. What comes next when this whole thing shakes out? What will the market look like?

“Clearly, we are in a period of weaker economic conditions that will likely depress steel demand, and it also very well may change the way we do business.” Moving from a traditional relationship-driven sales strategy towards online sales models is a looming challenge that Ganem is prepared to face. “I don’t know if that will go away completely, but I will not be surprised to see a move toward more online sales. We’re well positioned for that. A world of reduced steel demand puts pressure on the overall business model and we’re going to have to address that on the cost side of the business and keeping driving our digital transformation until we’re well ahead of the curve,” he mused.

“We were on our way, but now we really have to accelerate the process and transform the business from front to back. We need to put the various tools that we’ve been developing into place and fully automate to reach the productivity levels we need in order to drive costs down. That’s the way we’re going to not only maintain but improve our results sustainably after the immediate impacts of the crisis will be gone: addressing the crisis from the standpoint of efficiency and productivity.”

Their Kloeckner Connect portfolio of solutions currently serves more than 650 customers with an estimated market share of $100 billion. Connect is comprised of the Part Manager customer interface that gives contractual customers real-time insight into Kloeckner Metals’ inventory levels from their tablets and provides visibility all the way back to the steel mill; the Direct online order tool provides access to the online product catalog, current inventory, and stock levels; and Electronic Data Interchange, which increases the speed and accuracy of transactions with both Kloeckner Metals and other business partners.

“We’re also developing Kloeckner Assistant, a technology that lets us read incoming emails, PDF files, and anything that’s sent to us electronically. It automatically downloads information into our ERP system, adds to that information and enables us to respond to customer inquiries in a matter of seconds. This quoting process used to take hours or even days depending on the size of the inquiry. We’re driving these efficiencies through the customer facing side, and at the same time we’re developing similar tools for internal use and for interaction with our supply base as well.”

“Every crisis requires radical thinking, and I would suggest that we shouldn’t expect that we’re going to quickly return to normal,” Ganem insisted. “If that’s the feeling and that’s what you’re counting on, I think you’re going to get yourself in trouble.”

Current circumstances are confirming the presence of the company’s all-in approach to digitization. “It was important for us to transform the business, and now we can really move it to the next level because we can see what the benefits are going to be. Leaders have to be willing to challenge the status quo, and this is the type of event that forces you to do that. You can’t sit there and wait for the market to bail you out. You need to really take the bull by the horns and have the courage to fundamentally transform your business and be ready for what the future holds.”

As a top-three steel service center player, Kloeckner Metals does not rely on imported steel. That strategy is essential to keeping a robust, dependable supply chain. “We feel we are considered a key strategic customer by all of our core domestic mill suppliers,” he added. “Those supply chains are as strong and as safe as anything out there. We are domestically oriented and our relationships are so deep and long standing that the risk to our supply chains is almost nonexistent.

“We also have facilities with significant processing capabilities,” he noted. “In terms of what we’re dealing with now with COVID-19, if one of our facilities has to be shut down for some reason— because of a state mandate or an outbreak—we have plenty of redundancy to make sure that our customers are taken care of.”

Having created an intensely collaborative, forward-thinking culture built on developing solid relationships with customers and suppliers is bringing benefits to the organization despite market uncertainty. “We believe in relationships, we believe in transparency, and in honest communication and our steel mill partners will tell you that we are always ethical in our approach, and take great pride in doing what we say we’re going to do.

“The overall culture we’re trying to create at Kloeckner Metals is one of challenging the status quo. We want to challenge every process. We apply technology and digital innovation to make us more efficient and more productive. If we’re not afraid of change and we embrace that type of thinking, that’s what’s going to propel us into the future and create a competitive advantage for us.

“We’re having the same conversations with our suppliers,” he added. “We’re working very closely together to automate the procurement process, trying to create transparency into our demand so they can better plan their production. We are moving into short lead-time programs to minimize the amount of inventory that is needed to be carried in the supply chain which creates a lot more flexibility for ourselves and more consistency for our steel suppliers. It all ties together. It’s not just on the customer side, but on the supplier side as well.”

The current crisis is a proving ground for digital strategies, and for Kloeckner Metals it is reinforcing their mandate to continually push back against traditional expectations and limited, inflexible modes of legacy performance.

“One of the biggest issues we had as an industry was a lack of transparency in information. If you needed to know how much steel we had on the floor for you, how much finished goods were in place, what our inventory positions were in relation to your part numbers, you’d have to pick up the phone and call somebody. You’d get an Excel spreadsheet that you’d have to read and then load into whatever system or spreadsheet that you used. That’s all at your fingertips now. That’s really the one of the key drivers in creating an excellent customer experience,” he said.

“This is our global strategy; we’re putting a lot of effort into it, and it is this type of crisis that we’re living through that is going to show why digitization is important.”

This article originally appeared in the June, 2020 issue of The Boss Magazine.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: