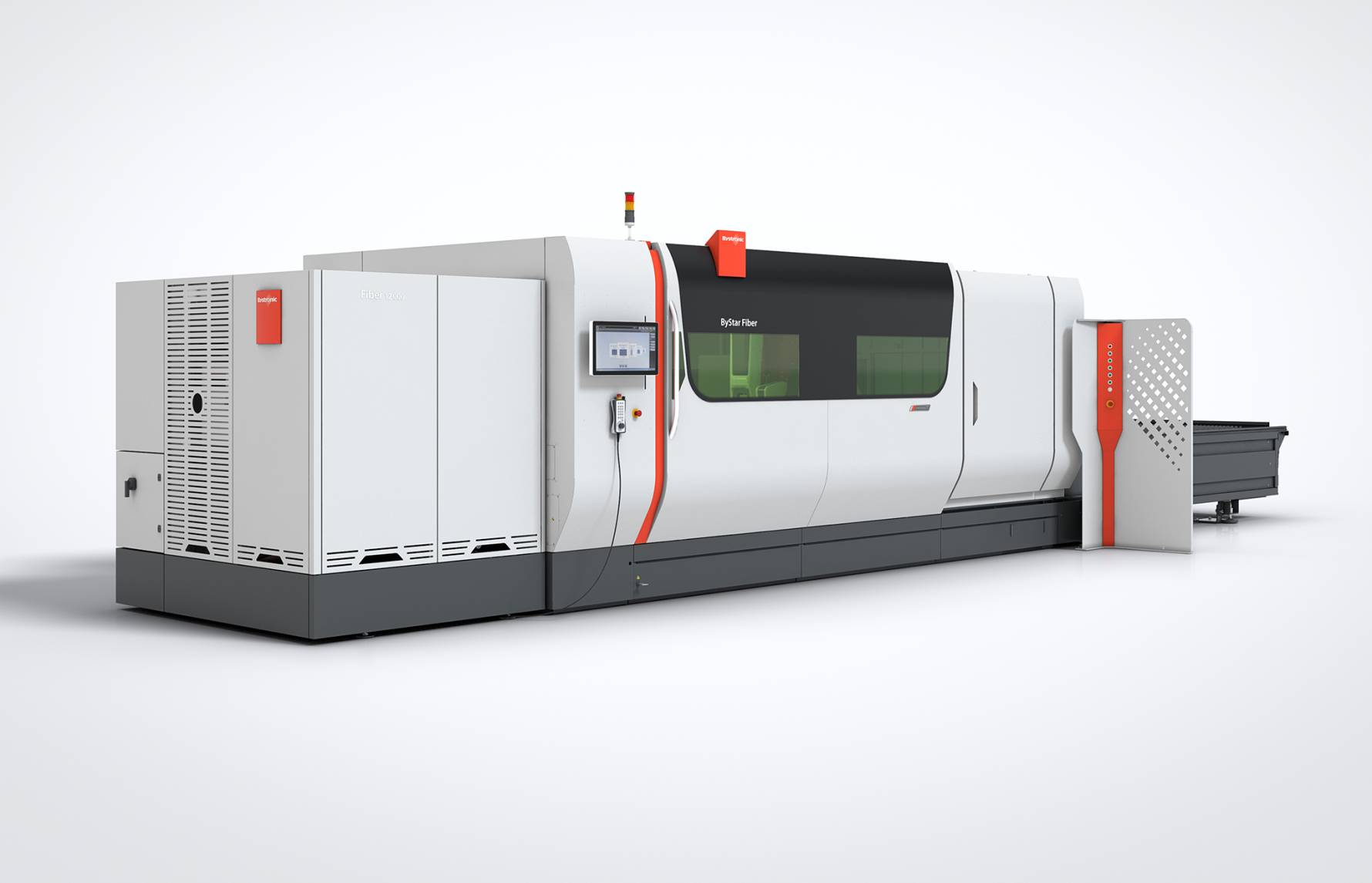

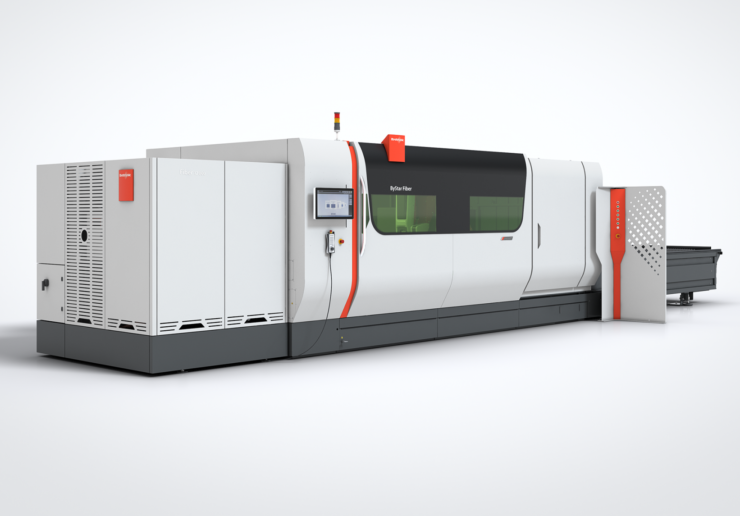

Late last year, the Bystar Fiber Bystronic became Kloeckner Metals’ latest state-of-the-art laser cutting equipment when it was installed at Kloeckner Charlotte. Fiber laser cutting has been one of the most disruptive technologies introduced to the metalworking market since CO2 lasers were first introduced for cutting sheet metal back in the 1980s. Fiber laser cutting equipment has completely impacted the entire status quo in sheet metal fabrication.

Laser cutting, as its name suggests, uses a laser to cut materials. The laser beam works by either melting, burning, or vaporizing materials like steel, leaving a high-quality finish to the remaining edge. In the 1960s, the first laser cutting machine was used to drill holes in diamond dies. A couple years later, the laser cutting equipment was fine-tuned to cut metals by blowing the laser with a jet of oxygen. By the ’70s, laser cutting was used in the aerospace industry to cut titanium.

The ByStar Fiber is able to cut any steel parts of up to 30 millimetres thick, whether galvanized, stainless, or heavy carbon, with an unprecedented precision that reduces drops and lessens losses. Solid state fiber lasers produce a much smaller spot size, up to 100 times smaller than carbon dioxide. This makes fiber lasers ideal for cutting reflective metals.

The 80 x 160 inch bed allows us to cut much larger parts than we were able to do before and the 21-shelf system handles 11,000 pounds of material per shift. We’re now running 44,000 pounds without an employee ever having to touch a sheet. Without having to do much manual labor, the operator’s job is to input customer specifications and make sure everything the machine needs is ready. The efficiency of the Bystronic ByStar Fiber also helps us reduce safety risks, a Kloeckner priority.

Since installing the Bystar Fiber Bystronic, Kloeckner Metals has substantially improved its scheduling and completion abilities, helping us maintain our reputation for just-on-time delivery with our customers. We live in an instantaneous society, where almost anything can be ordered with a click of a smartphone and delivered in days. The steel industry is no different: customers expect easy ordering and prompt deliveries.

Whether we like it or not, the role of technology in the steel industry is expanding and will only keep growing in the future. Businesses owe it to their operations, employees, and bottom line to invest in the latest technological innovations, including laser cutting equipment. Kloeckner is committed to digitization, and one key part of that is taking advantage of the latest laser cutting equipment, allowing us to work more efficiently, delivery higher quality product, and pass on the savings to our customers.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: