The power transmission pole demands durability and flexible design. The best construction solution, therefore, is steel. Strong and durable, steel can be shaped, welded, bolted, or molded into the exact structure you need. It can also meet the load requirements that power transmission pole industry standards demand.

The first power transmission poles were erected in 1843 alongside the Great Western Railway, and they were used to hold up telegraph wires. Telephone poles popped up the next year, and by 1889, many Americans had declared a war on poles, declaring them ugly and intrusive.

Over time, however, the poles won out, and today, 180 million utility poles populate the U.S. landscape. Originally, most poles were constructed out of wood. In 1998, however, steel started to become popular since it lasts longer, is better for the environment, and is more durable than wood. Every year, two million wood poles have to be replaced.

Kloeckner Metals is a full-line steel supplier and service center. Download our structural plate spec sheet to see in greater detail what A572 Kloeckner Metals routinely stocks.

Since 1998, the American Iron and Steel Institute, U.S. power companies have installed more than one million steel poles. Over 600 of 3,100 power companies now use steel to create their power transmission poles.

The utility pole market, which includes telephone poles and other similar structures, is projected to grow steadily in the coming years. The ongoing need for infrastructure improvements and the increasing demand for reliable and efficient energy transmission and distribution are driving this growth.

In addition to utility poles, there is a burgeoning demand for light poles and towers commonly used for street lighting and other outdoor applications. These structures must be able to withstand extreme weather conditions and provide consistent lighting in all types of environments. To ensure this level of performance, many light poles and towers are made from materials such as steel, aluminum, or concrete.

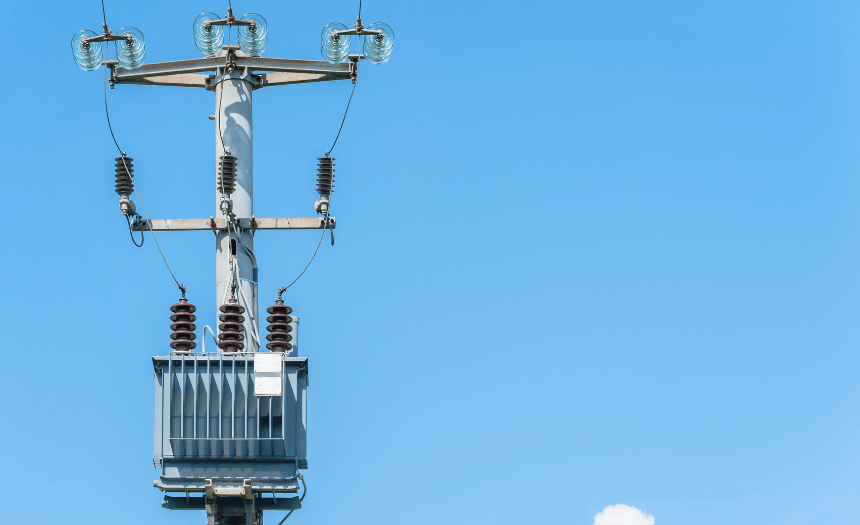

Power transmission poles, also known as mono poles or wood pole equivalents, are another critical market segment. These structures are designed to transmit high-voltage electricity across long distances and must be able to withstand extreme weather conditions and support heavy loads.

Machined base plates and pole centers are important components of these structures, providing the necessary support and stability to keep the poles upright and secure. As the demand for reliable and efficient energy transmission continues to grow, so will the market for power transmission poles and related products.

Power transmission and distribution poles must meet load requirements and industry standards. Consequently, the process of manufacturing these poles is complex and involves multiple stages. It typically begins with producing metal sheets in coil form, made from ASTM A572-65. The first stage of the process involves burning the metal sheets into trapezoids using plasma on a burn table.

Manufacturers use 2,000-ton press brakes to form the trapezoids into tapered poles. Original Equipment Manufacturers (OEMs) then take the burned trapezoidal flat sheets and turn them into poles. All the poles sit on machined base plates that are mounted on the ground that have to be pre-heated, squared, mated, and welded to the penetration joint.

Kloeckner Metals is a leading distributor of metal products and provides value-add strategic equipment that helps customers solve some of their biggest challenges in the power transmission pole and distribution industry. One of the primary challenges that Kloeckner Metals solves for customers is distribution. With multiple locations across the country, Kloeckner Metals can quickly and efficiently deliver metal products to customers, reducing lead times and ensuring that orders are fulfilled on time.

Another key problem that Kloeckner Metals solves for customers is the need for high-quality machined base plates. Base plates are a critical component of power transmission poles, providing the necessary support and stability to keep the poles upright and secure. Kloeckner Metals offers machined base plates made from high-quality A572-50 and A572-65 charpy tested plates processed on plate processing centers like the Kinetic K5200. This state-of-the-art equipment can burn, drill, tap, bevel, and scribe, ensuring that each base plate is precisely machined to meet each customer’s specific needs.

Kloeckner Metals also offers toll processing for second-stage processors. Focused on quality, efficiency, and customer service, Kloeckner Metals is well-positioned to help customers solve their most pressing challenges and achieve their business goals.

The company serves a diverse range of power transmission pole and distribution customers. These include OEMs and second-stage processors also rely on Kloeckner Metals for toll-processing services. These processors weld the tapered poles together to form complete structures. Kloeckner Metals provides machined base plates made from ½” thru 3” thick.

In addition to OEMs and second-stage processors, Kloeckner Metals also serves end-users or down-stage fabricators who have all the necessary equipment to make poles.

Kloeckner Metals provides high-quality plate processing services and machined base plates that are critical components of producing utility poles, towers, and light poles. By offering these services, Kloeckner Metals enables its customers to focus on their core competencies, such as pole fabrication and assembly, and achieve greater efficiency in their production processes. This results in cost savings, improved product quality, and faster time-to-market for the end-users.

Kloeckner Metals primarily offers ASTM A572-65 plate, sheet, and coil products designed to produce power transmission poles, utility poles, towers, and light poles. These products are manufactured to meet strict industry standards, including IEEE specifications, and are charpy-impact tested to ensure that they can withstand significant forces and impacts without falling over.

One of the key benefits of using ASTM A572-65 plate products is that they are high-strength, low-alloy (HSLA) materials that offer excellent weldability, formability, and machinability. This makes them ideal for producing utility poles and other critical infrastructure components that require high strength and durability.

Most of the projects Kloeckner Metals serves are funded by public utilities and involve government agencies. This means that there is typically a high level of regulatory oversight and stringent quality requirements that must be met to ensure the safety and reliability of the infrastructure. By providing high-quality, Charpy-impact tested ASTM A572-65 products, Kloeckner Metals helps its customers meet these requirements and deliver power transmission pole products built to last.

In the market for A572 steel? Kloeckner Metals is a full-line steel supplier and service center. We combine a national footprint with the latest fabrication and processing technologies and the most innovative customer service solutions.

Steel base plates are fundamental elements employed in various manufacturing...

Metal fabrication is a critical process that transforms raw metal...

The solar industry has undergone a significant transformation by incorporating...

X

The Kloeckner Metals website uses modern technologies. Unfortunately, your browser doesn't support those technologies.

Download the latest version of one of these browsers to experience the site: